|

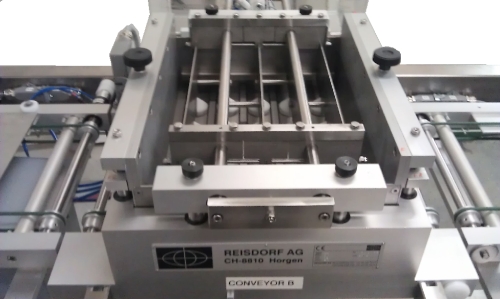

Dosing and Pressing

The Dosing and pressing machine is designed to dose and compress certain dry ingriendents with any type of binder. The product is stencilid directly onto the oven band by a retraction system.

The advantages of this type of depositing are:

-

Higher productivity

-

Adequate for Florentine powder and similar materials

-

Width's 800mm to 1200mm

-

Speed up to 4 Meters / Minute

-

Precise product shapes

-

Machine with retraction system, synchronized with oven conveyor

-

Exchangeable template for new shape: 30 Minutes

General Information

-

Machine frame in St.4301 completely mounted and machined to carry the former machine adjustable machine support feet to adapt existing oven conveyor height.

-

Trolley section with Servo drive according to conveyor speed and row arrangements. Roller guidance with coil cover on all guiding bars.

-

Former machine with retraction system (500 mm) in V2a complete mounted according to all functions.

-

Base frame with drives

-

Dosing and Forming cylinders

-

Dosing template with former plates to avoid conveyor contact

-

Kinematical movement arrangement of the stroke functions

-

Safety guards

Other functions

-

Counter plate made of food proved bras and mounted on frame attachment

-

Height of the plate adjustable to conveyor and forming machine

-

Electric controller in V2a mounted opposite of the operation side on the machine frame. (ca. 150 mm from floor)

-

Operation panel near the operation side, mounted to the machine frame

-

Synchronization with conveyor speed by Encoder and mechanical speed measuring Pulley

DA Laboratory machine

This version of machine is designed for laboratory purposes.

|